Microencapsulation

- Microencapsulation is the process by which tiny liquid droplets or solid particles are suspended or coated with a continuous film of polymeric material.

- Product known as: microcapsules

- Size : micrometer to millimeter (<1mm)

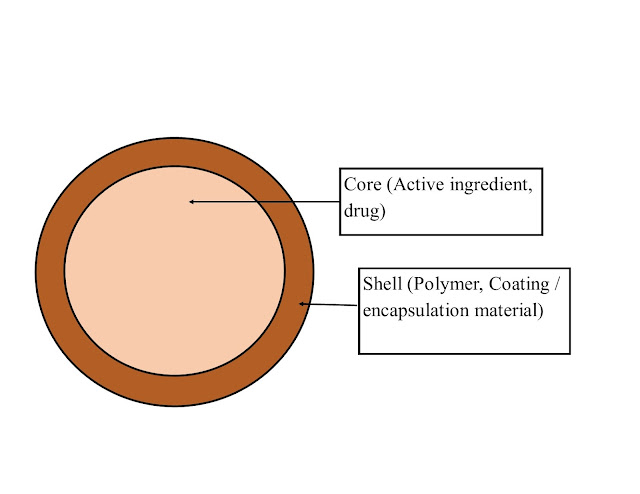

Parts of microcapsules:

1. Intrinsic part (inner): Core: contains active ingredient.

2. Extrinsic part (outer): Shell: comprises polymeric material.

- The shell protects the core from external atmospheres.

- Core material exists in the form of either a solid, liquid and gas.

- Core materials --> solutions, suspensions, emulsions.

- Core material and shell materials should be compatible with each other.

Morphology of microcapsules:

- Mononuclear microcapsules: contain the shell around core.

- polynuclear microcapsules: contain many cores within a shell.

- Matrix microcapsules: core material is evenly distributed inside shell material. i.e. API (drug, core) is dispersed in shell (polymer).

|

| polynunclear and matrix microcapsules |

Different techniques used for microencapsulation:

Chemical processes: suspension, dispersion and emulsion polymerization, polycondensation.

Physico-chemical processes:

Coacervation, layer-by-layer assembly, sol-gel encapsulation,

Supercritical

CO2 assisted microencapsulation.

Physico-mechanical process:

spray drying, multiple nozzle spraying, fluid-bed coating, centrifugal technique, vacuum encapsulation, electrostatic encapsulation.

Microencapsulation processes with their relative particle size ranges:

|

Microencapsulation

process

|

Size

(micrometer)

|

|

Extrusion

|

250-2500

|

|

Spray-drying

|

5-5000

|

|

Fluid bed

coating

|

20-1500

|

|

Rotating

disc

|

5-1500

|

|

Coacervation

|

2-1200

|

|

Solvent

evaporation

|

0.5-1000

|

|

Phase

separation

|

0.5-1000

|

|

in-situ

polymerisation

|

0.5-1000

|

|

Interfacial

polymerisation

|

0.5-1000

|

|

miniemulsion

|

0.1-0.5

|

|

Sole-gel

encapsulation

|

2-20

|

|

Layer-by-layer

assembly

|

0.02-20

|

|

Class

|

Coating materials

|

|

Water soluble resins

|

Gelatin, gum arabic, starch, polyvinyl

pyrrolidone, carboxymethyl cellulose, hydroxyethyl cellulose, methyl

cellulose, arabinogalactan, polyvinyl alcohol, polyacrylic acid.

|

|

Water insoluble resins

|

Ethylcellulose, polyethylene, polymethacrylate,

polyamide, poly(ethylene-vinyl acetate), cellulose nitrate, silicones,

poly(lactide-co-glycolide)

|

|

Waxes and lipids

|

Paraffin, carnauba, spermaceti, beeswax,

stearic acid, stearyl alcohol, glyceryl stearate.

|

|

Enteric resins

|

Shellac, cellulose acetate phthalate, zein.

|

Comments

Post a Comment